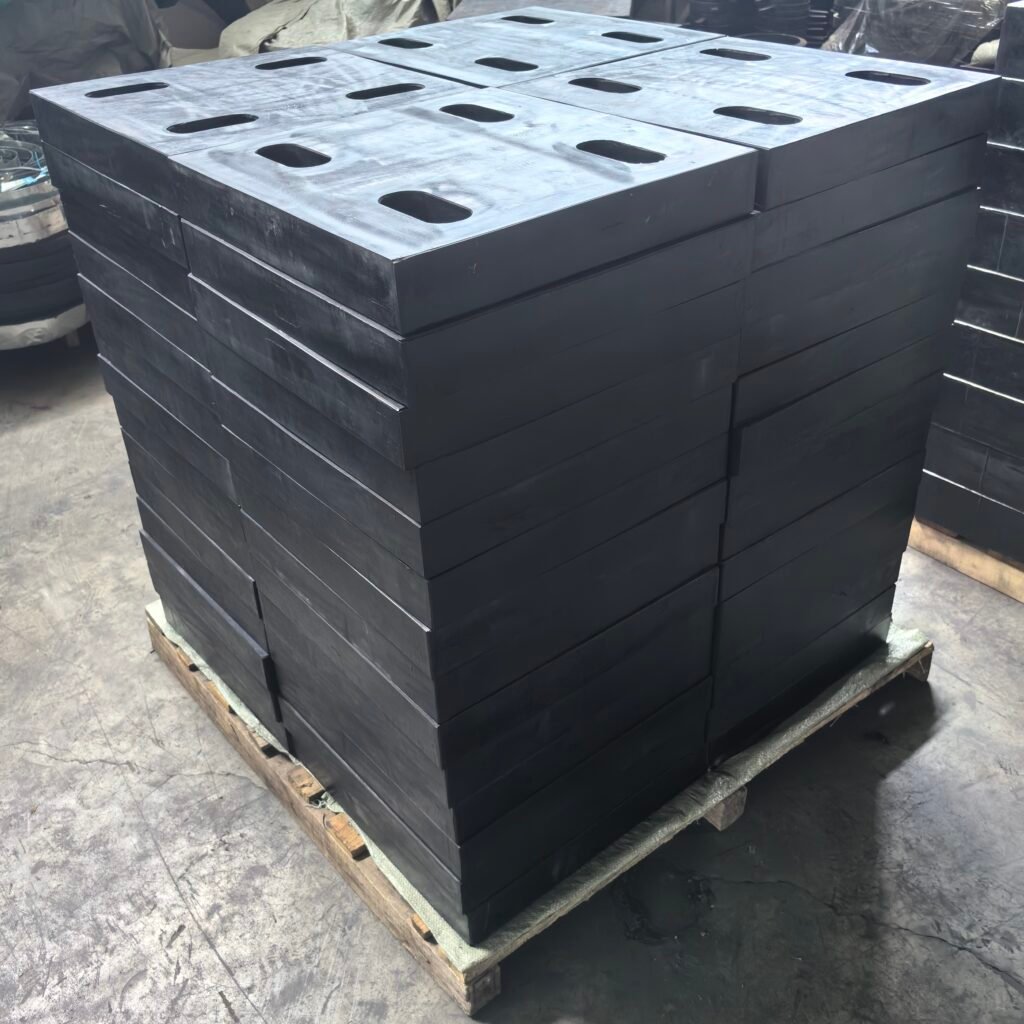

Laminated elastomeric bearings are a fundamental component in modern bridge engineering, prized for their cost-effectiveness and reliable performance in small to medium-span bridges.

Firstly, they are highly economical. Their simple construction—comprising alternating layers of steel plates and rubber—results in a mature manufacturing process and a significantly lower cost compared to more complex bearing types, helping to control overall project budgets.

Secondly, they offer comprehensive functionality. They effectively combine load-bearing, displacement, and rotation capabilities. Their vertical stiffness reliably transfers superstructure loads, while the rubber layers accommodate horizontal movements from thermal expansion and contract, as well as minor beam-end rotations.

Finally, installation and maintenance are straightforward. Their compact design allows for easy installation and replacement. With excellent durability and minimal maintenance requirements, they effectively reduce long-term operational costs.

What other advantages are you aware of?